The industrial sector has witnessed significant advancements in machine parts, driven by the need for higher efficiency, durability, and precision. Modern manufacturing requires components that can withstand rigorous conditions while maintaining optimal performance. Leading suppliers of machine parts and specialized equipment, including the Texwrap machine, are pushing innovations that enhance productivity and reliability in industrial applications.

Advanced Materials for Enhanced Performance

One of the most notable developments in machine parts is the use of advanced materials. High-strength alloys, composite materials, and heat-resistant metals improve durability and reduce wear under extreme operating conditions. Similarly, innovations incorporated into the Texwrap machine components enable extended service life and superior performance, ensuring consistent operation even in demanding packaging environments. Using the right material for each machine part optimizes both performance and cost efficiency.

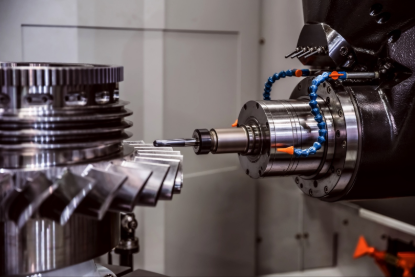

Lightweight and Durable Designs

Modern machine parts are designed to be both lightweight and durable, reducing energy consumption and facilitating easier handling. Techniques such as CNC machining, precision casting, and additive manufacturing enable the creation of complex geometries that optimize strength-to-weight ratios. For instance, key elements in the texwrap machine utilize these design innovations to improve efficiency without compromising durability, highlighting the benefits of cutting-edge engineering.

Wear-Resistant Coatings and Surface Treatments

Wear and corrosion are critical concerns for machine parts in industrial settings. Advanced surface treatments, such as nitriding, ceramic coatings, and polymer-based films, provide excellent protection against abrasion and chemical damage. These treatments extend the life of machinery components and enhance operational reliability. The texwrap machine also benefits from such surface enhancements, ensuring smooth operation and minimal maintenance requirements over time. Additionally, these coatings improve resistance to extreme temperatures and harsh chemicals, making machinery more versatile across different industrial applications. Regular inspection and reapplication of protective layers further ensure long-term performance and safety of both machine parts and equipment, like the Texwrap machine.

Smart Technologies and Automation

The integration of smart technologies has revolutionized the design of machine parts. Embedded sensors can monitor vibration, temperature, and stress in real-time, enabling predictive maintenance and reducing the likelihood of failures. Automated features in the texwrap machine, such as sensor-guided wrapping and adjustable tension systems, further illustrate how innovative design and technology improve efficiency and safety. Smart components allow manufacturers to optimize both machinery performance and operational costs.

Modular and Standardized Components

Standardization and modularity are increasingly important in modern machine parts. Modular components simplify assembly, reduce downtime during repairs, and allow for easier upgrades. Components in the Texwrap machine also follow these principles, offering interchangeable parts that streamline maintenance and enhance flexibility. Standardized designs improve production efficiency and simplify inventory management for manufacturers that rely on multiple types of machinery. Moreover, modular machine parts enable faster adaptation to evolving production requirements, thereby reducing the costs associated with redesign or replacement. This approach also enables seamless integration of new technologies into existing systems, ensuring long-term operational scalability.

Sustainability and Energy Efficiency

Sustainable practices are a growing focus in modern machine parts design. Materials that reduce friction, lightweight components, and energy-efficient manufacturing techniques minimize environmental impact. Even the texwrap machine incorporates energy-saving designs and durable, recyclable components, contributing to greener industrial processes. These innovations support long-term operational efficiency while promoting sustainability in the manufacturing process.

Conclusion

Innovations in materials and design have transformed the landscape of machine parts, providing enhanced durability, efficiency, and reliability. From advanced alloys and wear-resistant coatings to smart technologies and modular designs, modern components meet the rigorous demands of today’s industries. Equipment like the Texwrap machine exemplifies how these advancements improve performance, reduce maintenance, and extend operational lifespan, making it an essential tool for modern manufacturing processes.